|

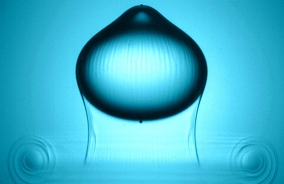

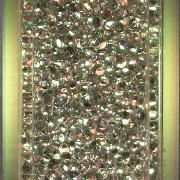

The incorporation of mineral particles into an elastomer in order to obtain a homogeneous composite material requires a lot of energy. Moreover, the homogeneity of the mixture at a mesoscopic scale, a feature that controls the mechanical properties of the composite material, is not guaranteed. This issue is of course crucial during the fabrication of the main component of tires. A homogeneous mixture can be obtained at the colloidal scale by working in aqueous phase. We have recently demonstrated that the control of the sol-gel transition at the colloidal scale of a suspension of natural rubber, an elastomer which is extracted from Hevea trees in the form of emulsion droplets (latex), and carbon black can lead to a homogeneous composite material. One of the major fundamental questions to be addressed is to understand the origin of the high reactivity between the two classes of particles and thus the underlying interactions that are involved in this remarkable irreversible heteroaggreation.

Industrial partnership: Michelin

|