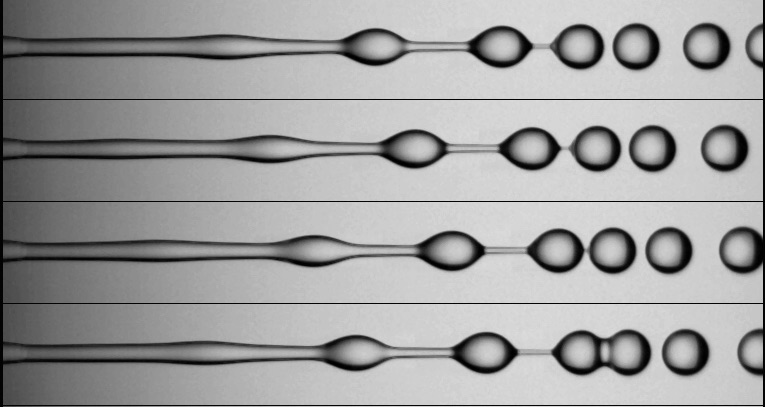

Liquid jets ultimately break up into droplets through an instability driven by surface tension. For highly viscous liquids, drops are connected by cylindrical liquid filaments whose radii linearly decrease with time, thus forming drops on a string structure. For a jet composed of two aqueous phases made in air by coaxial extrusion, we observe that, for moderate Weber and capillary numbers, drops slow down with different velocities, leading to drop coalescence. The origin of the traffic collision is linked to the spatial feature of the capillary instability where capillary and viscous forces acting on the drops evolve along the jet and ultimately amplify small velocity fluctuations. The emergence of such fluctuations is related to the unstable nature of the annular coflow of liquids having contrasting viscoelastic properties. From a practical point of view, flow and actuation conditions can be adjusted to inhibit drop collision and thus drop coalescence. These findings allow then the fabrication of monodisperse submillimeter core-shell objects based on the fragmentation of compound jets made of polymer solutions that find applications for three-dimensional cell culture.

H. Doméjean, J. Bibette, and N. Bremond, 2016, Traffic collision during the breakup of an aqueous viscous compound jet. Phys. Rev. Fluids, 1, 063903.

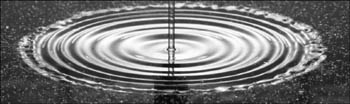

The formation and fragmentation of liquid sheets resulting from the oblique collision of two identical cylindrical jets is investigated. The liquid expands radially from the impacting point forming a sheet in the form of a bay leaf bounded by a thicker rim. The sheet shape, rim size and liquid velocity field are quantified and represented analytically. External harmonic perturbations of the injection conditions reveal the nature of the rim destabilization and of its coupling with the sheet. Flow perturbations in the incident jets lead to sheet thickness modulations which trigger the fragmentation of the rim via the formation of liquid ligaments whose dynamics is described. The breakup of these ligaments induce both the shape and width of the drop size distribution in the spray formed by this process.

N. Bremond, E. Villermaux, 2006, Atomization by jet impact. J. Fluid Mech., 549, p. 273-306.

The fragmentation of a laminar undulating liquid sheet flowing in quiescent air is investigated. Combining various observations and measurements we propose a sequential atomization scenario describing the overall sheet-drop transition in this configuration. The undulation results from a controlled primary Kelvin-Helmholtz instability. As the liquid travels through the undulating pattern, it experiences transient accelerations perpendicular to the sheet. These accelerations trigger a secondary instability responsible for the amplification of spanwise thickness modulations of the sheet. This mechanism, called the 'wavy corridor', is responsible for the sheet free edge indentations from which liquid ligaments emerge and break, forming drops. The final drop size distribution is of a Gamma type characterized by a unique parameter independent of the operating conditions once drop sizes are normalized by their mean.

N. Bremond, C. Clanet, E. Villermaux, 2007, Atomization of undulating liquid sheets. J. Fluid Mech., 585, p. 421-456.

The breakup of a free thin liquid film subjected to an impulsive acceleration is investigated. A soap film is stretched on a frame at the exit of a shock tube. As the shock impacts the film, the film accelerates within a very short time and detaches from the frame at a constant velocity function of the shock strength. The liquid thickness modulations amplify and eventually the film is perforated with a number of holes, subsequently growing in radius and connecting to each other. The initially connex film is left in the form of a web of liquid ligaments which break into droplets. Both the hole density and formation time depend on the film velocity. We analyse these observations with an impulsive Rayleigh-Taylor instability incorporating liquid surface tension. It is shown to account for both the mode selection and its associated time of growth, providing a criterion for the film bursting time and hole density.

N. Bremond, E. Villermaux, 2005, Bursting thin liquid films. J. Fluid Mech., 524, p. 121-130.

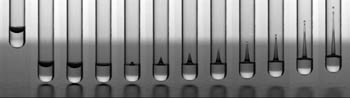

A tube filled with a perfectly wetting liquid falls axially under its own weight. In its gravity-free reference frame, the liquid interface is deformed by surface tension into a hemispherical shape. On impact of the tube on a rigid floor, the interface curvature reverses violently, forming a concentrated jet. If the contact angle at the tube wall is such that the interface is flat, the liquid rebounds as a whole with the tube, with no deformation. We analyse this phenomenon using an impulse pressure description, providing an exact description of the initial liquid velocity field at the impact, supported by high-speed image velocimetry measurements. This initial dynamics is insensitive to liquid surface tension and viscosity.

A. Antkowiak, N. Bremond, S. Le Dizès, E. Villermaux, 2007, Short-term dynamics of a density interface following an impact. J. Fluid Mech., 577, p. 241-250.

A. Antkowiak, N. Bremond, J. Duplat, S. Le Dizès, E. Villermaux, 2007, Cavity jets. Phys. Fluids, 19, 091112, (Gallery of fluid motion).